LP-RIM

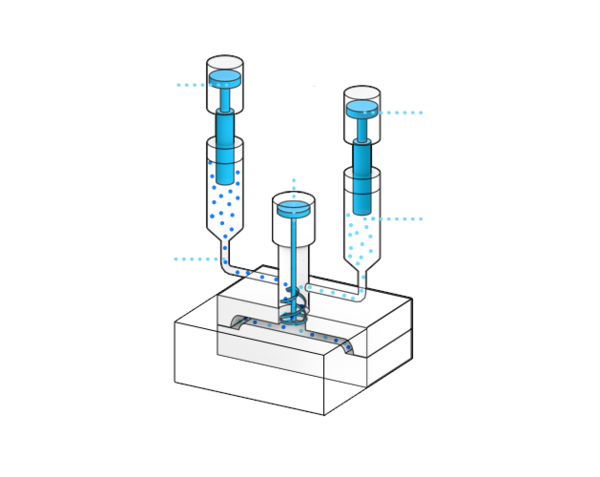

In the reaction injection moulding (RIM) process a solid form is filled with polyurethane under 2-4 bars of pressure using an appropriate batcher. The polymerization occurs directly inside the tool.

The advantage of using the RIM process is that there is no need for a casting machine. This means that the size of the parts produced is not limited to the size of the machine. Special mention should be made of the high tool durability of a couple of hundred pieces, the ease with which pieces with a minimal slant can be disassembled when using a releasing agent and the good surface qualities of the pieces. This technique especially allows for an excellent price-performance ratio which cannot be reached using other similar processes.

Using this technique, prototypes can be created that are almost identical to the finished series with respect to wall thickness, surface-quality and the quality of fine details.

Quantities greater than 100 pieces can quickly be created using the RIM process, which is therefore also suited for low-volume production. Vehicle accessories such as spoilers or electronic housings for the medical industry are produced using this process.