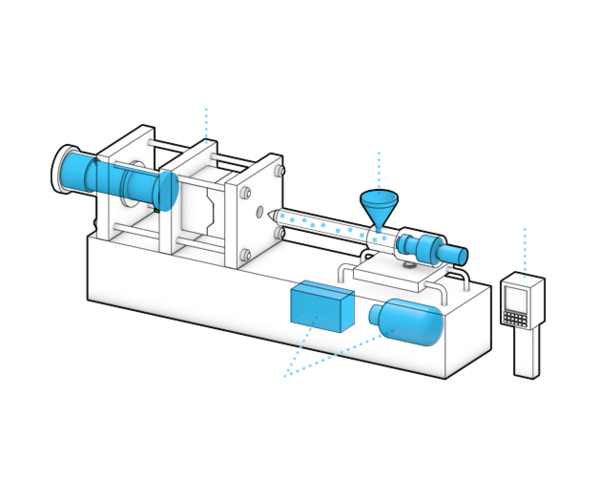

Injection moulding

Whenever highly precise prototypes made out of the production-material are needed in greater quantities, we rely on the advantages of prototype casting.

On the basis of CAD-data we construct and produce the necessary tools needed for this procedure in our own tooling facilities. This guarantees a quick and flexible response to any customer demands. Generally, the fact that all facilities are in-house allows us to produce cast parts up to 300 x 200 x 200 mm within a few days.

Many rapid tooling strategies can be used for the production of prototyping tools:

Aluminium tools

Production of casting tools made of aluminium using HSC and erosion, loose parts instead of sliders for deforming undercuts.

Cast resin tools

The master mould is filled with aluminium cast resin.

A generatively produced master model is used to mould the tool made of aluminium-filled cast resin. This method can be used in combination with milled core pins etc.

Generative tool production

Direct production of the necessary tools through the use of layer manufacturing processes such as selective laser sintering, etc.

Hybrid tools

Different production techniques combined in one tool.

Aside from the low cost per part, the major benefit of using one of the prototype tooling techniques listed here, is that parts can be manufactured at the start of production using the already existing prototyping tool, even if the tool used for series production is not yet ready.