Vacuum Casting

Vacuum casting is a follow-up procedure used in conjunction with a stereolithographoc model and a silicone form that allows us to produce polyurethane castings models quickly and affordably. Depending on the complexity of the prototype 15 to 25 pieces can be created using one silicone form.

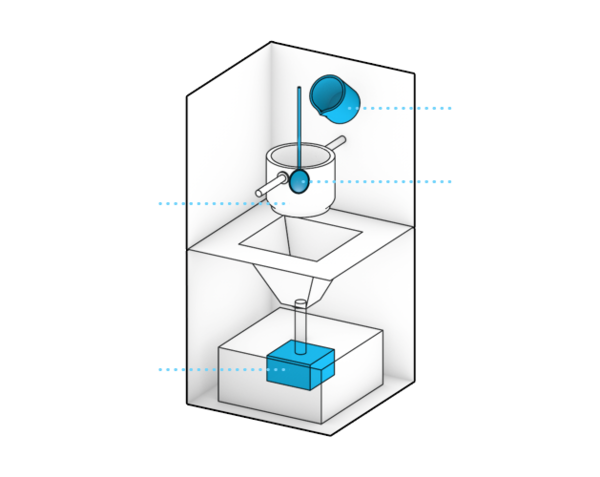

A silicone form is placed inside a vacuum chamber and is filled with polyurethane through a feed channel. During this process, the vacuum sucks out any air trapped inside the silicone form, thus making sure that no air bubbles form in the finished prototype. This allows the production of high-quality, complex prototypes for numerous purposes such as functionalatiy tests, fittings or near series tests.

Using our machines we can cast two and three component parts using the vacuum casting procedure.

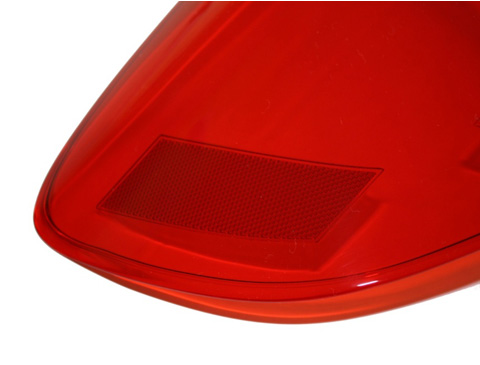

The variety of polyurethanes available is so great that almost any material used in the finished product can be imitated using this process. It is even possible to create transparent, fibreglass strengthened, coloured and rubber prototypes, so that, in conjunction with an appropriate surface finish, a near-perfect model can be created.

Using this process, standard parts as well as shaped parts (such as bearing sleeves or stud bolts) can be integrated into the finished prototype seamlessly during the casting process.