Stereolithography (SLA)

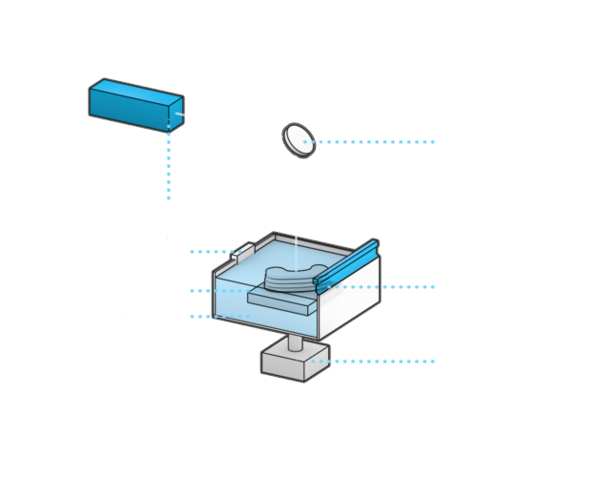

The process known as Stereolithography generates a prototype out of 3D CAD-data. The CAD-data received from the customer is first translated into very thin cross-sections. A UV-laser is then programmed to trace out each cross-section on the surface of a container filled with liquid photopolymers. The laser initiates a reaction that hardens a thin layer of the polymer. This cross-section is then lowered and liquid photopolymer is used to coat the cross-section using a wiper system. The laser then traces the next cross-section and thus, the process repeats itself until the finished prototype is generated. This technique allows us to produce a model within a couple of hours, without mechanical machining and without having to cut and model by-hand.

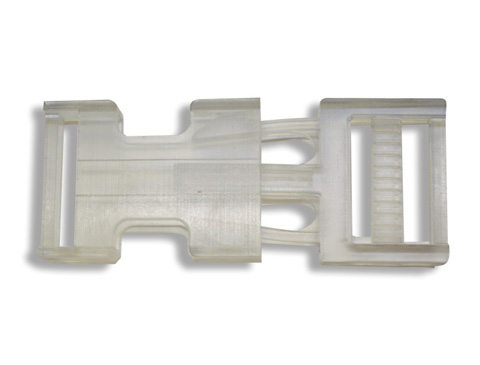

Stereolithography-models are usually used to build a silicone tool for applications in vacuum casting later on. Additionally they can also be used as conceptional, geometric, display and functional models.